Introduction to Forging parts for roller shaft head, advantages, characteristics and principles of forging

Forging parts for roller shaft headthe forging machine is used to exert pressure on the blank.,After forging, its structure and mechanical properties can be improved.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Forging parts for roller shaft head.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Forging parts for roller shaft head.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Forging parts for roller shaft head can be improved.,is a kind of high quality and low price Forging parts for roller shaft head,the product looks atmospheric.,be loved by our customers.。The following is to introduce the Forging parts for roller shaft head:

1、Brief introduction of Forging parts for roller shaft head

Forging parts for roller shaft headis the metal that exerts pressure to shape the required shape or appropriate compression through plastic deformation.,is a popular Forging parts for roller shaft head。

Forging parts for roller shaft head

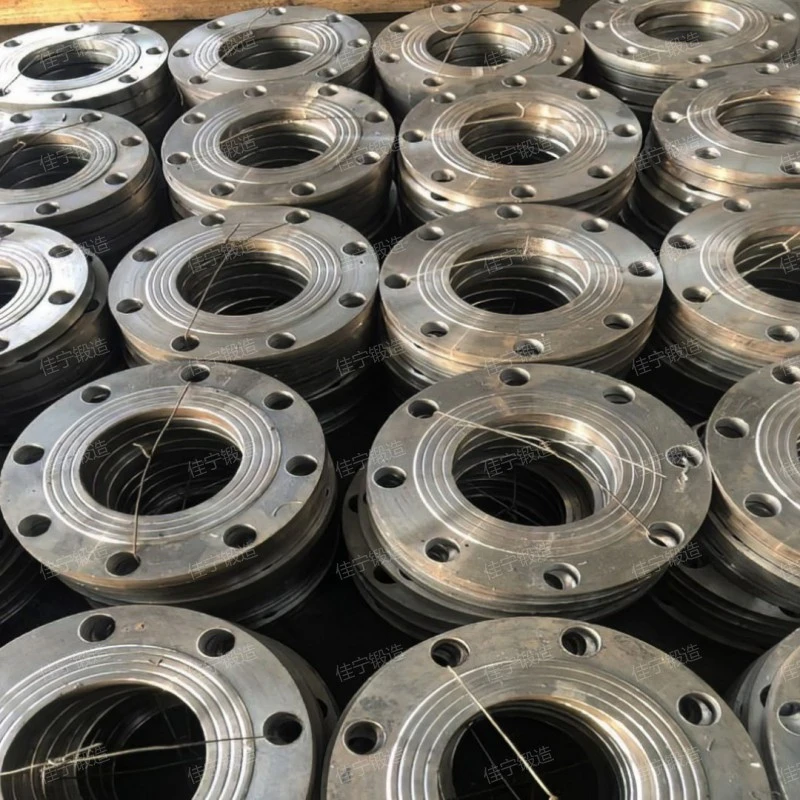

2、Forging parts for roller shaft head working site

You can buy Forging parts for roller shaft head according to your needs and show you Forging parts for roller shaft head videos.。

Forging parts for roller shaft head

As you can see from the live video.,Jianing forging features include Can bear large impact force or heavy load., high-precision, Great forging flexibility, high-intensity and High productivity。

3、Introduction of advantages of Forging parts for roller shaft head

The advantages of Forging parts for roller shaft head are as follows:

- Eliminate internal defects

- Replace other processing methods

- High degree of automation

- Good fatigue resistance.

- High dimensional accuracy

During the forging process, the porosity, shrinkage cavity, cracks and other defects in the metal are closed under the action of high temperature and pressure, thus improving the structural integrity of the Forging parts for roller shaft head.

In some cases, Forging parts for roller shaft head can replace parts produced by other processing methods (such as casting, welding, etc.), thus simplifying the production process and improving production efficiency.

Modern forging equipment has a high degree of automation, which can realize continuous and efficient production and greatly improve production efficiency.

The particle flow inside the Forging parts for roller shaft head flows precisely along the contour of the part, and these continuous streamline lines are beneficial to reduce the incidence of fatigue or common faults.

In the forging process of Forging parts for roller shaft head, high dimensional accuracy and shape accuracy can be obtained through the precise forming of dies.

Forging parts for roller shaft head

4、Forging parts for roller shaft head characteristics

Forging parts for roller shaft headthe main features are Save raw materials, Good anti-fatigue performance, Light weight, Good mechanical properties and Save raw materials,it is widely used inenergy,manufacturing industry,war industry,metallurgy,shipping and other industries。

Forging parts for roller shaft head

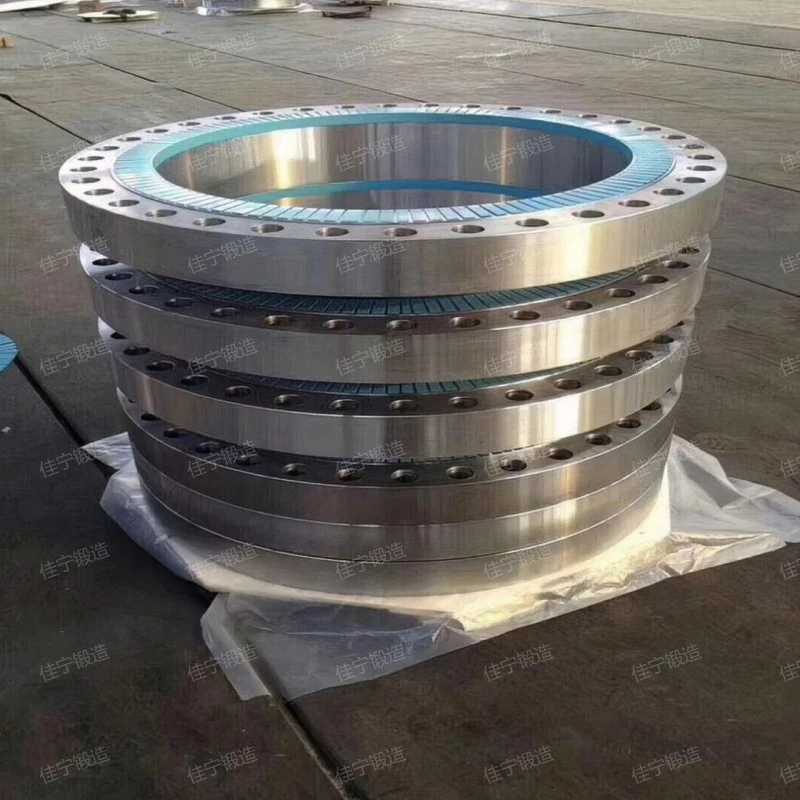

5、Physical picture of Forging parts for roller shaft head

High-definition pictures of Forging parts for roller shaft head of different specifications and models,the product looks beautiful., reliable in quality and trustworthy.。

Forging parts for roller shaft head

Note: All the pictures in this article were taken by Jianing manufacturer.。

6、Forging parts for roller shaft head quotation

The Forging parts for roller shaft head price is introduced as follows:

- Low cost of raw materials

- Proper management mode

- Different regions

- Quality advantages and disadvantages

- select a qualified person

Cost plays a decisive role in the price. The cost mainly includes the initial investment of the product, such as time, manpower and materials selected. The more the investment cost, the higher the relative product pricing. On the contrary, the less the input cost, the lower the price.

Jianing forging has long used the sales method of small profits but quick turnover to sell products, and the product price, market price and ex-factory price are the same. The purpose of this is to improve the sales volume of products and the visibility of enterprises.

Geographical location also has a certain influence on the formulation of price, because there is a close relationship between geographical location and transportation cost. Generally, the price of places with superior geographical location will be more fair, which is lower than that of those remote cities. Jianing the site is located at:Xinzhou, where the traffic is very developed and convenient, provides a series of conveniences for the distribution of products to a great extent.

The Forging parts for roller shaft head is made of high-quality materials, and the cost of the product is high, so the price of the product will also rise. Jianing forging has always adhered to high quality in the construction of Forging parts for roller shaft head and won the trust of customers.

Different manufacturers have different material selection standards. The better the quality of the selected materials, the more expensive the products will be. On the contrary, the prices will be low. However, to avoid customers being deceived, compare several products of the same specification and model before deciding to purchase.

Forging parts for roller shaft head

Forging parts for roller shaft headis a Forging parts for roller shaft head,it has been widely used in energy, war industry, pressure vessel, power, construction machinery and other industries,the product looks atmospheric.。

Related recommendation

-

What is a Carbon steel pressure vessel flange ring? Introduction to the principle of flange structure

2025-5-26 -

热作工具钢锻件

2024-12-10 -

What is a 12Cr2Ni4 free forging? How much is the price of the forging?

2025-5-26 -

What is a Flat welded steel pipe flange with protruding surface? flange specifications, models, and parameters

2025-5-26 -

Introduction to Internal gear ring forgings, how much is the price of the ring gear?

2025-5-26 -

65Mn车轮锻件

2024-12-10 -

Introduction to Rolling ring free forging and forging structure principle

2025-5-26 -

Introduction to 316L stainless steel threaded flange plate and flange advantages and features

2025-5-26 -

Introduction to Stainless steel convex panel flat welding flange ring, flange advantages, characteristics and principles

2025-5-26 -

Introduction to Ring connection surface flange cover, introduction to flange advantages and characteristics

2025-5-26