What is a Forged parts of power shaft? Introduction to the Working Principle of forging

Forged parts of power shaftrefers to the workpiece or blank obtained by forging metal blank.,Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Forged parts of power shaft can be improved.、After forging, its structure and mechanical properties can be improved.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.,support customization。The following is to introduce the Forged parts of power shaft:

1、Brief introduction of Forged parts of power shaft

Forged parts of power shaftthe forging machine is used to exert pressure on the blank.,is an advanced Forged parts of power shaft developed by our company in combination with the actual situation of the industry。

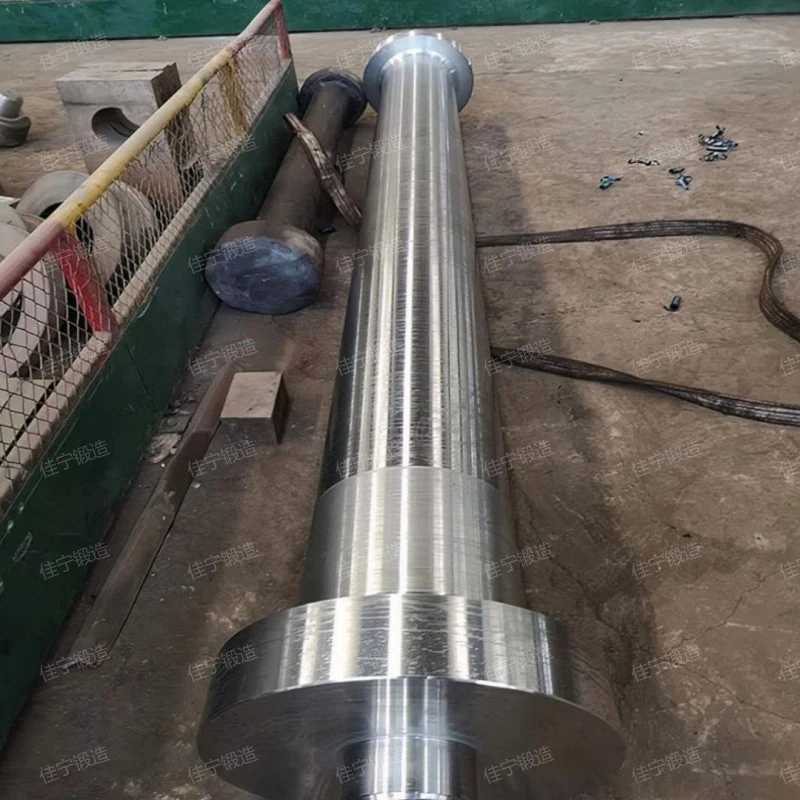

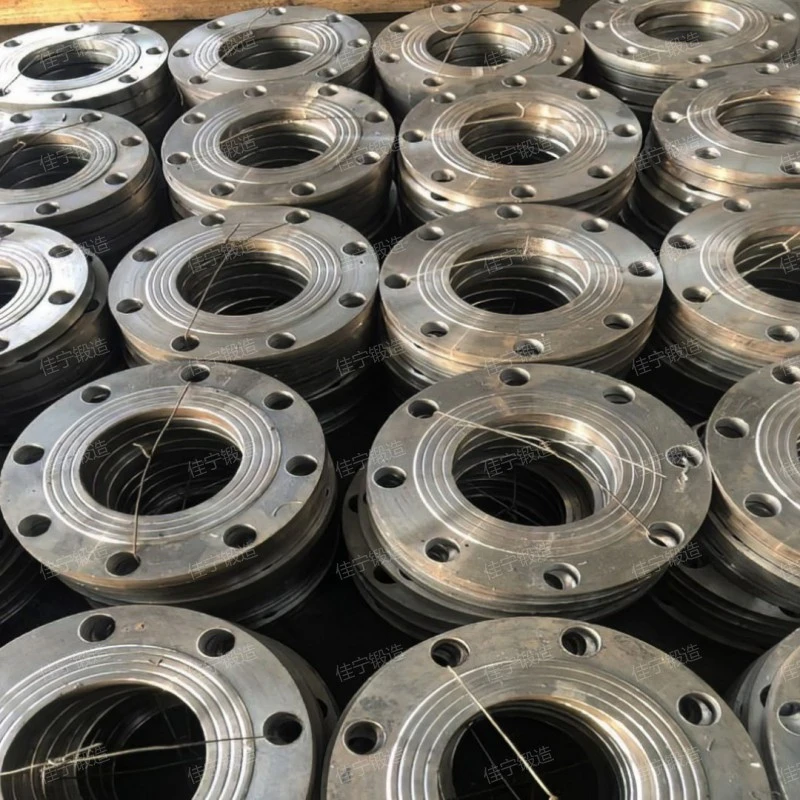

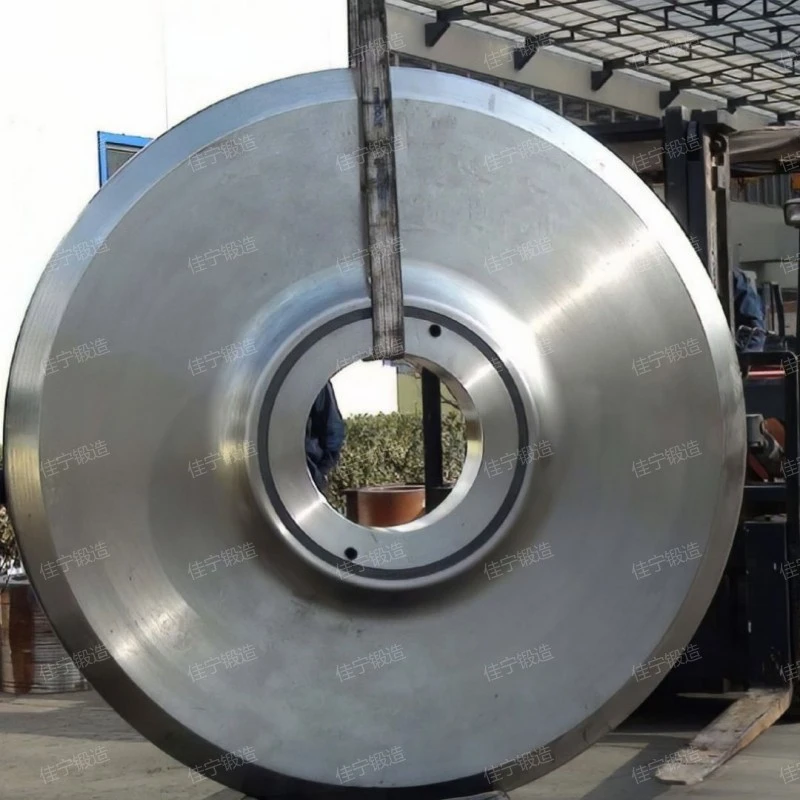

Forged parts of power shaft

2、Forged parts of power shaft HD picture

The details of the Forged parts of power shaft are displayed in many directions, and the Forged parts of power shaft is beautiful and cost-effective.。

Forged parts of power shaft

Note: All the pictures in this article were taken by Jianing manufacturer.。

3、Forged parts of power shaft performance advantage

Forged parts of power shafts have the following advantages.

- High dimensional accuracy

- high tenacity

- Replace other processing methods

- Reduce the amount of subsequent processing

- Optimizing structural design

In the forging process of Forged parts of power shaft, high dimensional accuracy and shape accuracy can be obtained through the precise forming of dies.

The fiber structure of the Forged parts of power shaft is reasonably distributed, which improves the toughness of the material and enables the Forged parts of power shaft to bear greater impact force and alternating stress.

In some cases, Forged parts of power shaft can replace parts produced by other processing methods (such as casting, welding, etc.), thus simplifying the production process and improving production efficiency.

The forming precision of the Forged parts of power shaft is high, and the subsequent processing amount is relatively small, thus saving the processing cost and time.

On the premise of ensuring the design strength, through reasonable structural design, the Forged parts of power shaft can be lighter than the casting, thus reducing the overall weight of the machine or equipment and reducing energy consumption and cost.

Forged parts of power shaft

4、Forged parts of power shaft introduction video

You can buy Forged parts of power shaft according to your needs and show you product videos.。

Forged parts of power shaft

As you can see from the live video.,Jianing forging the advantage is After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Forged parts of power shaft can be improved.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.。

5、Forged parts of power shaft advantage

The advantages of Forged parts of power shaft are as follows:

- Perfect quality assurance system

- Good fatigue resistance.

- High dimensional accuracy

- Good chemical uniformity

- Improve material utilization rate

In the process of Forged parts of power shaft production, a perfect quality assurance system is established, and the raw materials, production process and finished product inspection are strictly controlled to ensure the reliable quality of the Forged parts of power shaft.

The particle flow inside the Forged parts of power shaft flows precisely along the contour of the part, and these continuous streamline lines are beneficial to reduce the incidence of fatigue or common faults.

In the forging process of Forged parts of power shaft, high dimensional accuracy and shape accuracy can be obtained through the precise forming of dies.

Forging can disperse the segregation of alloy or nonmetal and make the Forged parts of power shaft have excellent chemical uniformity.

In the process of Forged parts of power shaft production, through accurate blanking and forging process, the utilization rate of raw materials can be maximized and waste can be reduced.

Forged parts of power shaft

6、Brief introduction of Jianing forging

Jianing is a professional and large-scale Forged parts of power shaft manufacturer, which has many years of production and operation, complete production facilities, skilled staff and high production capacity and product quality. It is a Forged parts of power shaft manufacturer trusted by consumers at present.。

Jianing forging

Forged parts of power shaftthe advantage is Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Forged parts of power shaft.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.,is a kind of high quality and low price Forged parts of power shaft,is a common Forged parts of power shaft。

Related recommendation

-

What is a Cone shaped forged parts? forging specifications, models, and parameters

2025-5-26 -

What is a Valve cover flange cover? Introduction to the advantages and characteristics of flange functions

2025-5-26 -

Introduction to Oil cylinder earring forging, introduction to forging function advantages and characteristics

2025-5-26 -

钻孔中空轧辊毛坯锻件

2024-12-10 -

What is a Reducing butt welding flange? Introduction to the Working Principle of flange

2025-5-26 -

What is a Concave flat welded steel flange cover? Introduction to the principle of flange structure

2025-5-26 -

Introduction to Square gear forgings, introduction to gear function advantages and characteristics

2025-5-26 -

Introduction to Axle head forging and forging advantages and features

2025-5-26 -

Introduction to National standard forged parts, advantages, characteristics and principles of forging

2025-5-26 -

Introduction to Welding variable diameter flange, introduction to flange function advantages and characteristics

2025-5-26